We do not currently have a selection tool for this product line, so please give us a call with your application questions.

- Compressors

- Alternators

- Generators

- Custom Bearing Supports

- Hybrid Vehicles

- and much more

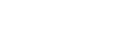

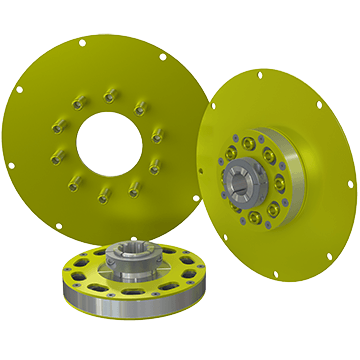

Armadillo Flywheel Couplings

The Hayes “Armadillo” Flywheel Coupling absorbs vibration and shock to provide a steady dampening effect.

The Hayes “Armadillo” Flywheel Coupling absorbs vibration and shock to provide a steady dampening effect.

The two-piece design gives you the ability to clamp onto both splined and keyed shafts which greatly reduces spline or shaft fretting corrosion. We have worked with many OEM’s to produce these flywheel couplings with multiple dynamic torsional stiffness values.

In today’s world of tough generator and alternator applications, this product has proven to lengthen the life of every application it has encountered. Call us today if you need a workhorse flywheel coupling for your custom application.

Hayes Manufacturing, Inc.

The evolution of Hayes Manufacturing from a small garage to a state-of-the-art manufacturing facility for stub shafts, splined couplings, flywheel couplings and drive couplings is nothing short of an American success story. The company has come a long way and is still growing.

In 1966, Hayes Manufacturing started out as a fledgling, family business in a garage in Rochester, Michigan where it was primarily a job shop. Today, Hayes makes stub shafts, flywheel couplings and drive coupling products in a 33,000 square foot facility in Fife Lake, Michigan. We employ skilled personnel who take pride in manufacturing our engine housings, drive couplings, spline couplings, pump mount plates and flywheel couplings in the USA. Hayes is certified to the ISO 9001 quality standard and the ISO 14001 environmental standard.

During all aspects of the manufacturing process of our flywheel couplings, pump mount plates, engine housings, drive couplings, stub shafts (and every one of our manufactured components), you can be sure that we employ rigorous quality standards and lean manufacturing practices. Hayes Manufacturing is constantly evolving its product line to meet the needs of customers– contact us today to discuss your application.